color case hardening temperature

Most of the newer receivers made today are made of pre-heat treated steel. 1425F is the minimum recommended case hardening temperature and it takes a lot less time at the maximum of 1625F.

Color Case Hardening Turnbull Restoration

Around 1400 BC hardening methods began to appear in armouries around the world.

. Of course the earliest ones were made out of bamboo. To achieve these results we use the traditional method of packing the component into a steel crucible together with a generous amount of charred bone wood and leather then heating the entire unit to a temperature of 1400. You have to watch the temperature more closely with color case hardening or the colors wont come out well.

Wyoming Armory is a custom gunsmithing shop where we build custom firearms but one of our specialities is tradional bone charcoal color case hardening. It was well known that the sharpness and hardness of a weapons edge could be enhanced by immediately plunging the newly formed weapon into cold water or oil after the item was heated up to the temperature required for forging. COLOR CASE HARDENING READ FOLLOW THESE INSTRUCTIONS 200 S.

Color Case Hardening. Posted on january 28 2017 by brian lohman. Engineering ToolBox - Resources Tools and Basic Information for Engineering and Design of Technical Applications.

You heat the part up red dunk it into the Kasenit compound and get a good coating. Color case hardening is the process of case hardening the surface of the metal. We keep our temperatures below hardening temperatures.

We keep our temperatures below hardening temperatures. Here at Tyler Gun Works we are able to Color Case items others cant due to our ability to work at lower temps. I made kind of a tree to wire the parts to as shown in the photos.

The thermal-shock is tre -. Color case hardening is a surface heat treating method and generally wont create the hardness desired for a cylinder. The colors are temper colors same as heating any piece of clean steel and are very thin one atomic layer and cannot be improved.

In the early days the steel was practically placed in a case of glowing coke. The tempering process of hardening steel. Kasenit and similar compounds are a lot easier to use and you can just use a torch.

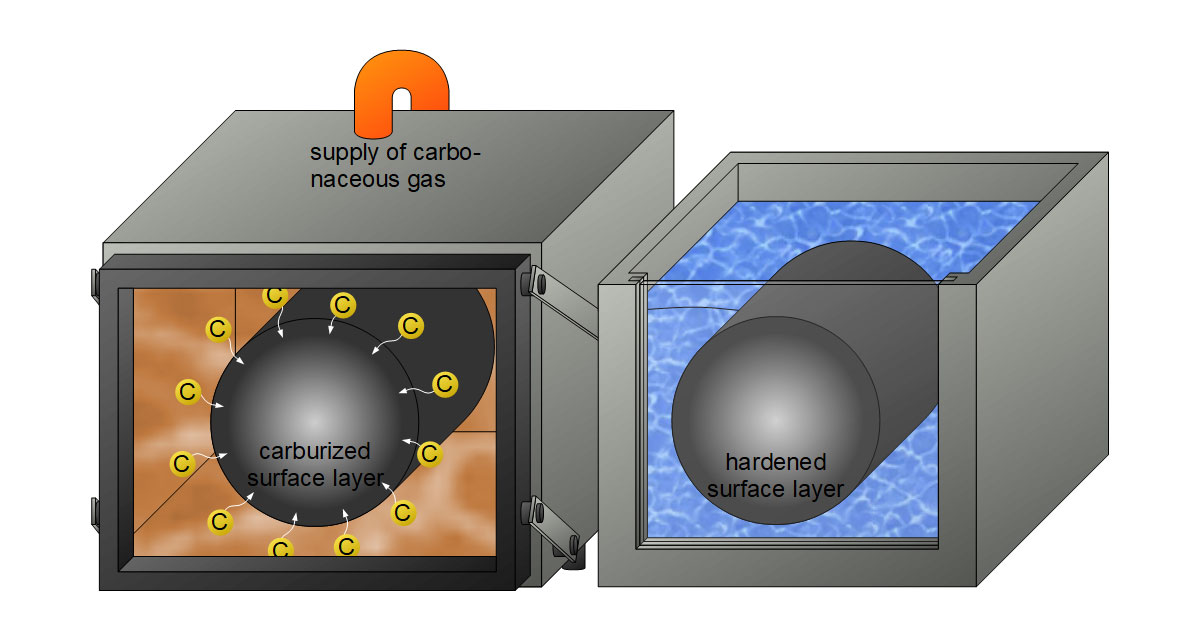

From the earliest guns that were made in the 10th century til the mid-late 1800s firearms were made of soft materials out of necessity. I used the large crucible box to case the receivers and used a smaller round crucible made of 4 12 pipe to case the miscellaneous parts. The carbon then diffuses into the surface layer where it leads to an enrichment.

Temperature Color of Heated Carbon Steel o F o C 600. WARNING Attempts to color case harden firearm components without proper train - ing in bracing and blocking procedures will likely result in warped and ruined parts. With quench temperatures no higher than 100 F.

Commonly referred to as Color Case Hardening. Recommendations to highly polish all parts and recommendations to not ex -. Cold chisels center punches.

Dont go over 1350 F. Hardening quenching tempering In case hardening a low-carbon steel case hardening steel with a maximum of 02 carbon is first exposed to a carbon-containing environment. Color case hardening steel ----- 1998.

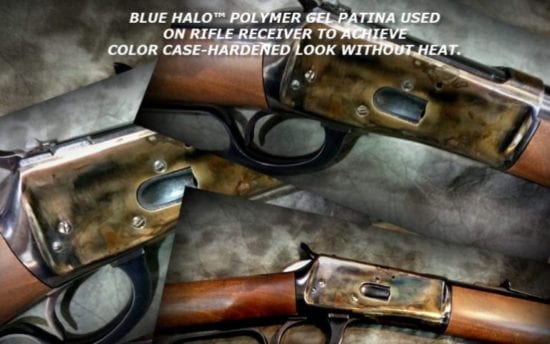

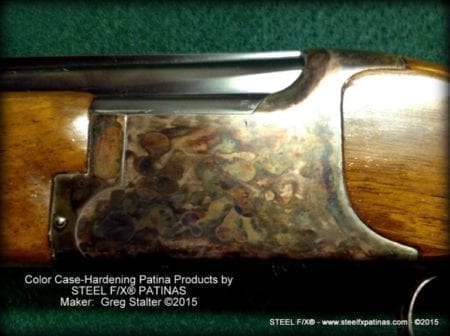

Color Case Hardening is a process for the surface hardening of steel which results in a decorative mottled-color finish. Typical oven temperatures range from 1350 F. Mike this coloring is part of the process of color case hardening.

Please email howell arms so we can provide you with a preliminary quote prior to shipping. The origins of case-hardening. To combat this fixtures are made to keep parts.

Wood to bone ratio was 31 and all other factors such as time and temperature remained. Secondly the method of color case hardening involves taking the metal part up to a certain temperature and then water quenching which has the possibility of warping the metal. Working at low temps gives us the ability to bring you the colors you deserve without double heat.

All of the parts received quite acceptable colors. This can be done in matte or gloss. Temperatures from 1250 to 1500 F and heating times of from 1 to 5 hours.

The History Of Case Hardening And Its Processes Double Stone Steel

American Handgunner When You Re Hot American Handgunner

Color Case Hardening Turnbull Restoration

Color Case Hardening Patina Kit

Color Case Hardening Patina Kit

Color Case Hardening Turnbull Restoration

Color Case Hardening Shooting Sportsman Magazine

Color Case Hardening Turnbull Restoration

Color Case Hardening Turnbull Restoration

American Handgunner When You Re Hot American Handgunner

Guns Magazine Case Hardening Redux Guns Magazine

Color Case Hardening Patina Kit

American Handgunner When You Re Hot American Handgunner

Color Case Hardening Turnbull Restoration

Color Case Hardening Turnbull Restoration

How To Do Color Case Hardening The Hobby Machinist

American Handgunner When You Re Hot American Handgunner